The Stub-EASE Process

Conduit “stub-ups” have been traditionally accepted in the concrete construction industry as a necessary evil. Until now, methods of protection and awareness have ranged from spraying the “stub-up” safety orange and taping a flag to them, to setting concrete blocks over the top of the “stub-up”. All the while, the hazards for trips, falls, and expensive damage (or potential loss) of the raceway were only being highlighted or hidden.

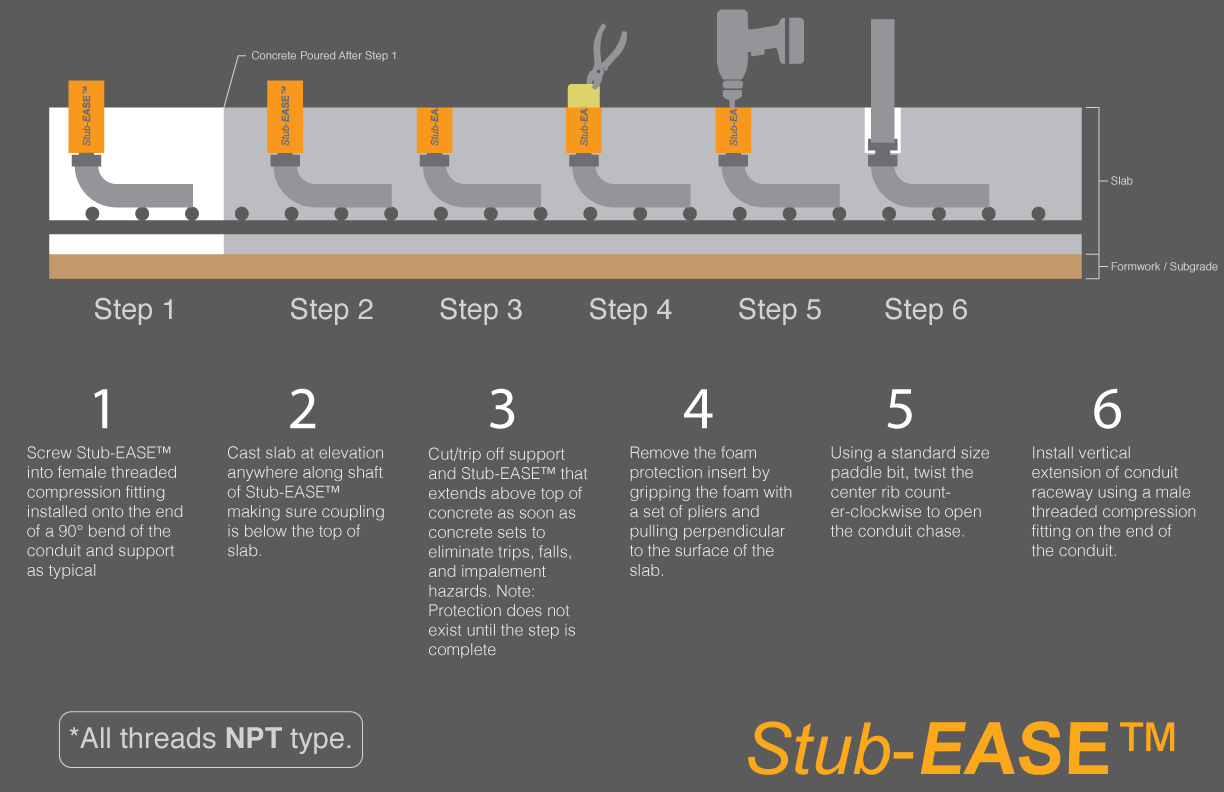

The concept is to maintain a coupling within the slab or below the grade of concrete to keep future extensions of the conduit from protruding beyond the top of concrete.

After the concrete pour, the HDPE (high density poly-ethylene) sleeve and support is cut down to the top of concrete elevation and left in the slab until the future raceway is ready to be safely extended into a wall cavity.

Then, the electrician will remove the foam insert, using a standard set of electricians pliers. The electrician will then extract the Stub-EASE by using a paddle bit, of the same size of the Stub-EASE in use. Once, the Stub-EASE is extracted, the electrician will be left with the perfect opening to attach their next piece of conduit.

The Stub-EASE can be installed onto the pipe by a laborer at the same time the pipe is being bent, therefore install does not have to take place on the deck. To remove the Stub-EASE, only basic tools are needed and the process should take approximately 30 seconds.

The following video shows the whole process, step by step.